Accuracy is king for most people when deciding what 3D scanner to get. So unsurprisingly, accuracy is usually one of the first specifications shared by 3D scanner manufacturers, but how do you know if they are being honest? Well, you measure it.

So let’s get into it and see how you can test the accuracy of a 3D scanner.

Establishing the Metrics

When professionals test a 3D scanner, they look for two things accuracy and detail.

- Accuracy refers to how close the 3D model’s dimensions are to the original object.

- Details mean the 3D scanner captures the object’s fine details clearly.

But today, we’re only looking at how to measure 3D scanner accuracy.

Measuring the Accuracy of a 3D Scanner

Typically, professionals in the 3D scanning arena use standard measurement tools such as a Ceramic Standard Ball, Ceramic Calibration Plate, or Step Calibration Block. These items have specific known dimensions, so they can be used to test a scanner’s accuracy quickly.

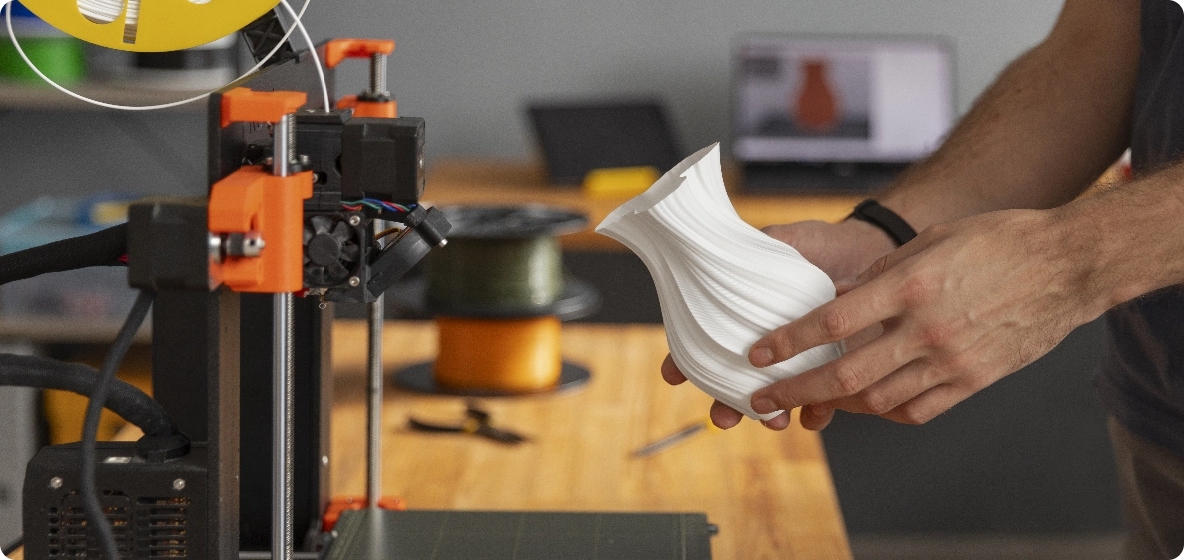

In the video below, we’re testing the POP 2’s accuracy using a Ceramic Standard Ball. So have a watch or keep reading, as we’ll also run through the process below and explain how you can test your scan without one.

In the video, the POP 2 is used to scan the Ceramic Standard Ball, then the distance from the exact center of one ball to the center of the other ball is measured to determine the accuracy. At the end of the video, we see that the distance, according to the POP 2, is 100.011898mm, while the official distance between the ball centers, as measured by the Shenzen Academy of Metrology & Quality Inspection, is 100.0397mm, so POP 2 is pretty accurate.

Okay, we realize it’s not practical for most people to buy professional measurement tools and get verification of said tool from a government agency, so let’s look at how to do it yourself.

How to Test Accuracy Yourself

You could scan an item with known dimensions, but remember that its official dimensions might be slightly off unless it was manufactured with incredibly tight tolerances.

The other way requires you to measure the object, ideally with a pair of calipers. To do this, you’ll need to take several measurements of the same distance and then work out the average, as measurement errors can and do often occur when manually measuring something.

When picking a point to measure, don’t randomly pick two points. Go for something like the diameter of an opening or the thickness of a specific part.

Once you’ve got your 3D model, load it up in your 3D modeling software of choice as long as it has a measuring tool. In the software, select the points you manually measured carefully, then compare the results to your measurements.

A Quick Quiz

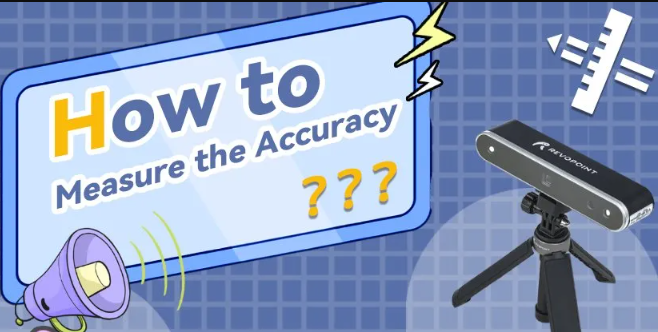

Check these pictures and guess which are accurate.

Yes, the first and second ones use the proper measurement method, while the third is questionable. Why? If you choose two points randomly, you cannot ensure that the two selected points represent the accurate distance between those two features.

So there you have it, an easy way to test a 3D scanners accuracy.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.