When considering 3D scanning for your next project, one of the first questions you might have is: how long does it take? This depends on factors such as the type of scanner, the object, and the desired level of detail. This blog will help you understand these variables to plan your projects more effectively.

Factors That Influence Scanning Time

Type of 3D Scanner

The technology behind the scanner significantly impacts how quickly you can complete a scan. For example:

- Standalone scanners, like the Revopoint MIRACO, don't need a PC so are pretty versatile and very fast to get ready. Scan typically take just a few minutes to accurately capture an object.

- Portable scanners, like the Revopoint POP 3 Plus take a little longer to set up as you connect to them to a phone or PC before starting the scan.

Object Complexity and Size

- Smaller, simple objects: A small, straightforward object can be scanned in as little as 2–5 minutes. The preparation time required for scanning small objects is usually short.

- Larger, detailed objects: Scanning intricate or larger objects might require more time, ranging from 10 minutes to an hour or more. For example, capturing the fine details of a sculpture could take significantly longer than scanning a basic box. Preparing to scan larger objects often takes more time as well. For example, setting up to scan a car will take significantly longer than getting ready to scan a toy the size of your fist.

Scan Settings

Higher-accuracy scans take longer as the scanner needs to capture more data. Standard accuracy may suffice if you’re scanning for general dimensions or an object with a lot of simple geometry, speeding up the process. However, for highly detailed models, like those used in jewelry design or reverse engineering, higher accuracy is a must.

Post-Processing Needs

The scanning process doesn’t conclude when the scanner stops. Cleaning up the scan data and exporting the model into a usable format can take anywhere from just a few seconds with one-click processing to 5 or 15 minutes when done manually.

Tips to Minimize Scanning Time

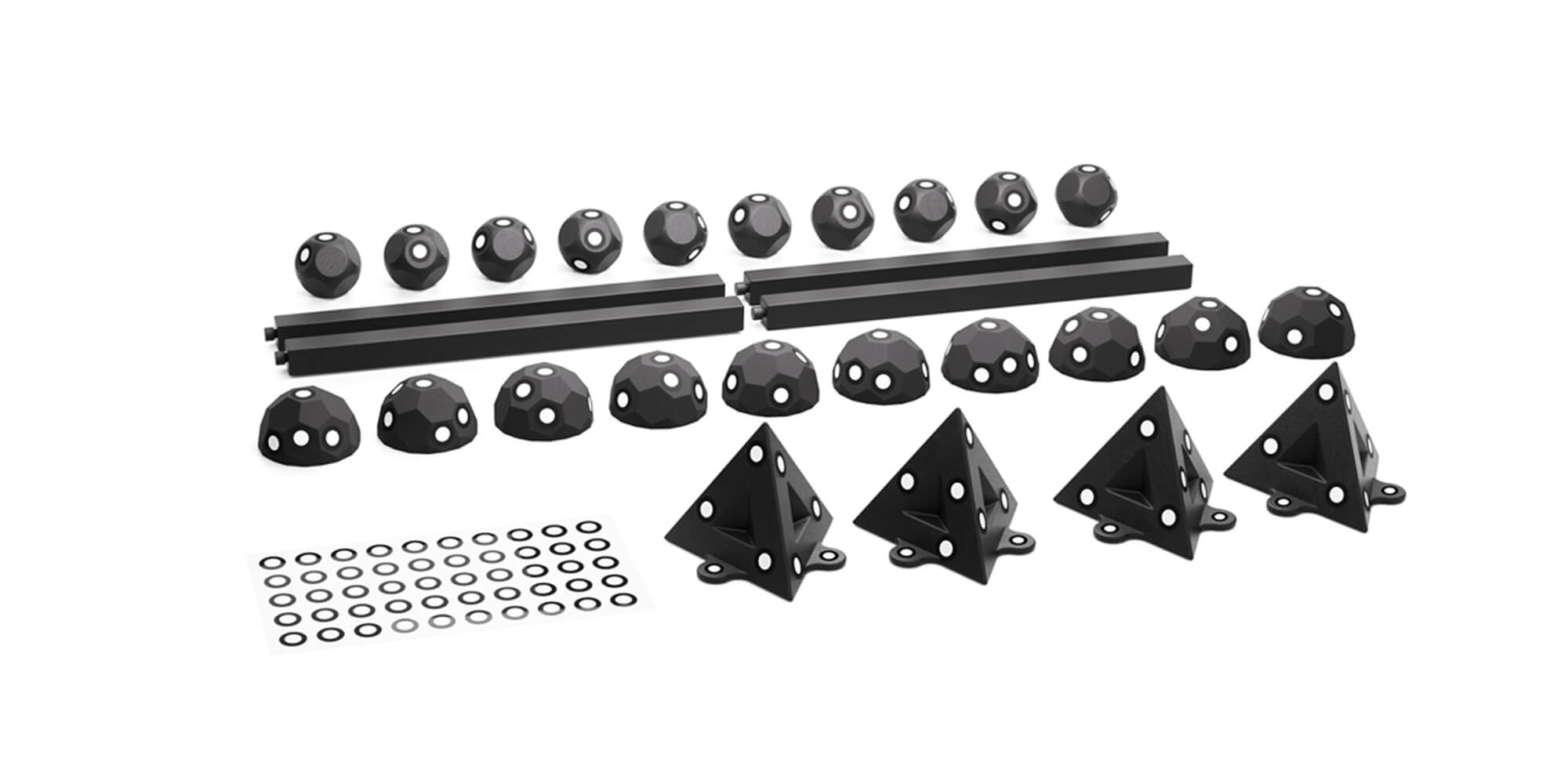

- Prepare Your Object: Clean your object and ensure it’s stable. For reflective or transparent surfaces, apply a scanning spray to make the surface dectable to the scanner. For featureless objects ensure that markers have already been placed.

- Choose the Right Equipment: Using a scanner designed for your specific needs, such as the RANGE 2 3D scanner to scan a person or large object, is much faster than using a POP 3 Plus for the same task.

- Optimize Scanning Paths: Practice makes perfect. Understanding how to position and move the scanner efficiently can significantly reduce the time spent capturing data and merging scans later.

Why Planning Scanning Time Matters

Understanding the time commitment for 3D scanning is crucial for industries ranging from manufacturing and healthcare to creative arts and gaming. By factoring in the type of scanner, object complexity, and desired detail level, you can better manage your project timeline.

Get Started Today

Want to experience efficient and accurate 3D scanning? Explore Revopoint 3D scanners to find the perfect option for your needs. Ultimately, using a 3D scanner is a game changer, offering speed and accuracy that traditional manual measurements or 3D modeling cannot match.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.