Accuracy and efficiency are vital in the fiercely competitive world of car modification. Few grasp this better than Sammie Lilly, the founder of Skreetkar3D. His journey from a teenage car enthusiast to the owner of an automotive modification company is a story of passion and ingenuity fueled by access to 3D scanning technology.

From Racer to Engineer

Sammie Lilly's story begins with his need for speed in his early days as a car racer. “I have been racing cars and modifying them since I was a teenager. As a racer, the competitive edge was always to make your own parts.” Sammie recalls. His custom modifications soon caught the eye of fellow racers, marking the birth of Skreetkar3D, a company specializing in the Ford Performance market, specifically superchargers and turbochargers.

In the early stages of his business, Sammie relied heavily on traditional methods such as calipers and manual measurements for CAD designs. However, these methods had their limitations. Sammie explains. “Traditional methods are usually limited to 2D planes, and complex curves usually don’t transfer accurately in a digital 3D space, limiting reverse engineering accuracy.”

Additionally, modern automotive parts, typically made of thin metal or flexible plastic, would, as Sammie says, “warp at rest on a table for measurement vs the intended shape on the vehicle.” The limitations of these traditional methods posed a significant obstacle to achieving the accuracy and efficiency that Sammie required to make his business thrive.

Supercharged by 3D Scanning

The turning point came when Sammie discovered 3D scanning technology. Initially drawn by its ability to gather all the necessary data for future projects at once, he quickly recognized the potential effect it could have on his work. “Having scanning data of the target object saves time from repetitive manual measurements, limiting the need for additional prototype fitments,” he notes.

Among the various 3D scanners available, Revopoint 3D scanners emerged as a clear choice for Skreetkar3D. “Revopoint scanners cost the same as a single rental charge (for high-end 3D scanners) and, in most cases, as accurate or at least good enough for the project,” Sammie explains. The affordability and accuracy of Revopoint scanners allowed Sammie to increase his profits as he no longer needed to rent expensive 3D scanners. Also, as he owned the device, he had the opportunity to practice extensively and continually refine his skills, enabling him to deliver even better results to his clients.

One of Skreetkar3D’s biggest successes so far is developing the Whipple supercharger thermal spacer kits for supercharged Mustangs. This product addresses a critical performance issue with supercharged Mustangs caused by excessive vibration and heat soak affecting throttle body electronics. “It's my most popular item that has solved a critical performance issue,” Sammie shares.

A 3D Workflow

Integrating Revopoint 3D scanners into Skreetkar3D’s workflow streamlined their processes. The typical workflow begins with understanding the customer’s needs and design requirements. The appropriate scanner is selected based on the rough size of the target area or part. Sammie shares, “Until the MIRACO, this was a tougher decision. However, this is now my go-to device since I can basically scan any size item that I usually work with.” Once Sammie captures the scan data, he meshes it, and reverse engineering is conducted using software like Geomagic DesignX or Quicksurface, depending on the project's complexity.

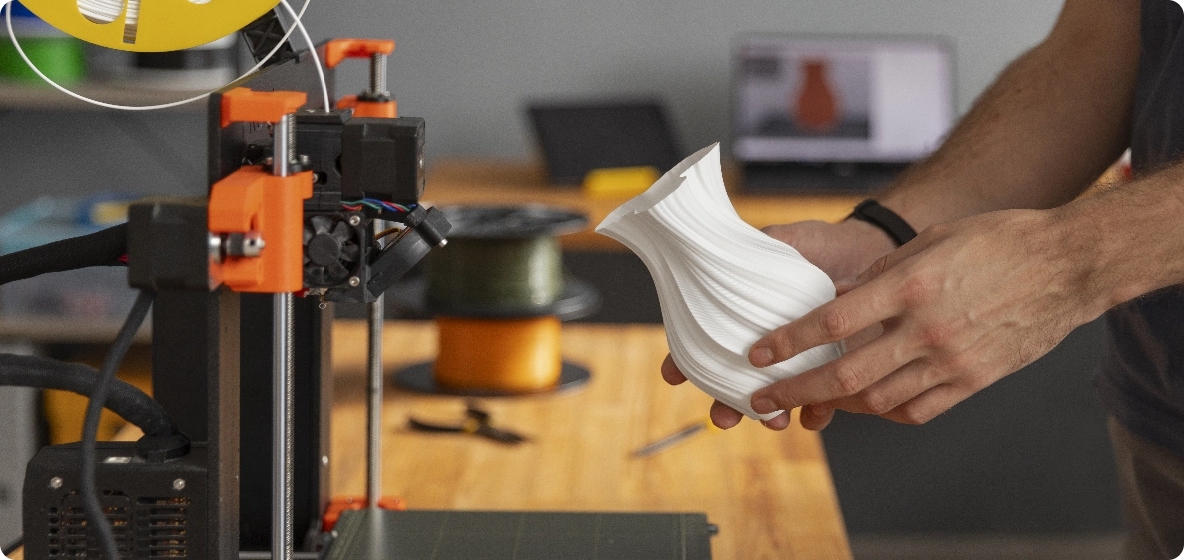

He then exports the file in STEP format to Fusion 360 to design the part. Once developed, Skreetkar3D moves on to rapid prototyping by creating 3D-printed prototypes for customer approval. “First, test prints are sent to the customer for test fitting. At this point, if tweaks are required, another test print is sent to the customer. Once the customer approves fitment. Engineering grade PA/PP/ASA materials are used for the final product, and they immediately go to market.” Sammie elaborates.

Advice for Aspiring Engineers

Sammie's advice is straightforward for those looking to venture into the automotive 3D scanning field: “Practice, practice, practice. I am still learning every day. The automotive racing industry, in particular, is a never-ending project that strives for innovation and solving a problem nobody has thought to solve yet.”

Skreetkar3D's adoption of Revopoint 3D scanners has enhanced the accuracy and efficiency of its car modifications, empowering them to continue pushing the boundaries of innovation and excellence in the automotive industry.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.